class a foam acts as a surfactant which means that it

Water Foam Class A concentrate is simply a surfactant similar to dishwashing soap that reduces surface tension. Aqueous film forming foam AFFF means a fluorinated surfactant with a foam stabilizer which is diluted with water to act as a temporary barrier to exclude air from mixing with the fuel vapor by developing an aqueous film on the fuel surface of some hydrocarbons which is capable of suppressing the generation of fuel vapors.

Adding A Punch To Fire Attack Enhanced Water Streams Firehouse

Class A foam is deployed through a variety of portable and fixed appliance devices ranging from firefighters backpacks brush and fire apparatus to rotary and fixed wing aircraft.

. SUNDepartment of Engineering Science University of Oxford Oxford UKT he presence of a surfactant in a gas-liquid system causes a substantial change indispersion properties. Class A foam is primarily a surfactant which is to say that it breaks down the surface tension of water. Class A foam is for use against Class A fires such as paper rubber textiles and wood.

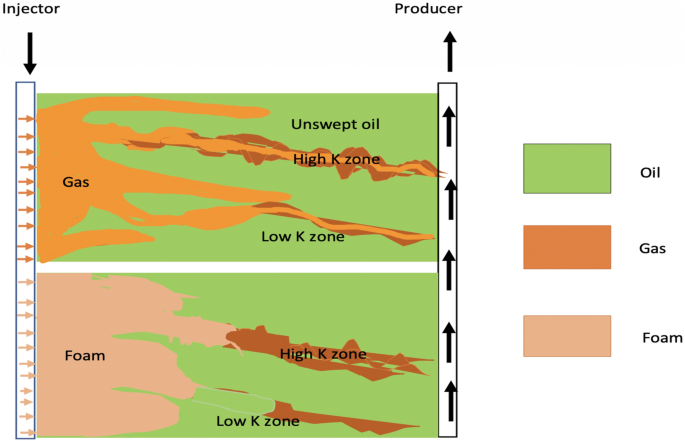

Denkov et al Role of surfactant type and bubble surface mobility in foam rheology Soft Matter 5 2009 3389 review. Class B foam is used on flammable liquids. As foam generation and also foam stability is a dynamic for process for generating and reducing surface area in a surfactantwater system the diffusion of the surfactant to the surface and the change in surface coverage at least locally during bubble generation and drainage of the film is a more useful way of explaining foam properties.

When mixed in correct proportions with water it can change two properties of the water. The foam blanket consists of a mass of bubbles which places a physical barrier on the exposed surface and acts as an insulating blanket. Environmentally responsible KnockDown a Class A foam concentrate is a unique formulation providing unmatched firefighting performance and flexibility.

In addition the portion of the foam concentrate molecule that repels other water in order. Class A foam is biodegradable and non-toxic so it is environmentally sustainable. This is nothing to do with drainage as explained in Drainage the walls contain an irrelevant.

Using Foam Increases Operational Efficiency. Class B foam on the other hand repels carbon. The second reason that surfactants help create foam is that the liquid in the foam walls is naturally sucked out of the walls into the edges.

So a surfactant which reaches the lowest surface tension for the least amount of surfactant is in general going to give an easier longer-lasting foam. Chemguard First Class is a non-corrosive non-toxic biodegradable Class A foam concentrate. This is a biodegradable mixture of foaming and wetting agents.

Costs of equipment Departments reported equipment costs up to 5000 per unit for nozzle-aspirated class A foam systems. Class A Foam Wildland Foam Class AB Foam Pyrocool Aqueous Film Forming AFFF Class A Foam Wildland Foam The foam is a non-corrosive non-toxic biodegradable concentrate. Tcholakova et al Role of surfactant type and concentration for the mean drop size during emulsification in.

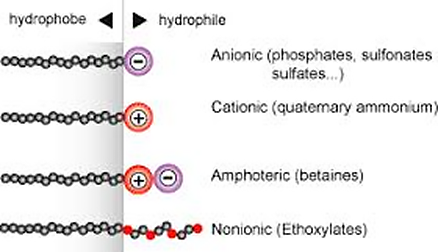

In particular AFFF manufactured by the 3M Corporation sold prior to. Surfactants are an extraordinary class of versatile amphiphilic compounds which have a spatially distinctive polar hydrophilic head and non-polar hydrophobic tail group. Class A foam will increase wetting effectiveness.

The negative charge helps the surfactant molecules lift and suspend soils in micelles. Due to its amphiphilic nature and unique feature of decreasing the interfacial tension the surfactant is widely used in every walk of life such as individual care products domestic cleaners. When used as a wetting agent the concentrate lowers the surface tension of the water allowing better penetration into deep seated fires.

During the overhaulmop-up process. These are prepared by direct electrochemical fluorination. DARTON FELLOW and K-H.

Because they are able to attack a broad range of soils anionic surfactants are used frequently in soaps and detergents. Water has a high surface tension and tends to bead up and cause run off. Class A foams are often intended for use at very low concentration of 01 to 1 and are formulated using environmentally favourable raw materials.

When mixed with water in the correct proportion it changes the properties of water. Class A foams may be used as a firefighting agent or as a fire barrier. Creation of fresh surface where the concentration of surfactant islower leads to a.

CAFS units may cost up to 40000 per vehicle. The pressure inside a foam of radius R that contributes to its self-destruction is 2γR. National Foams Class A Foams are also wetting agents.

This is a biodegradable mixture of foaming and wetting agents. When added to water the resulting foam solution consists of many smaller droplets with much more surface area allowing faster heat absorption. Anionic surfactants have a negative charge on their hydrophilic end.

Many wildland firefighters including rural and small urban. One class of fluorosurfactants used in AFFF formulations is based on perfluorooctyl sulfonate PFOS and structurally related compounds. Class A foam is used on common combustibles such as paper wood and textiles.

Is Class A foam environmentally friendly. An example would be like cooling a glass of water with a single ice cube. Class A foams are blend of surfactants that enable strong wetting and foaming properties.

As a fire barrier Class A foams increase moisture con-tent in Class A combustibles preventing the ignition of these type fuels. Water draining from the foam blanket soaks into exposed Class A fuel and retards further combustion. THE EFFECT OF SURFACTANT ON FOAM AND FROTHPROPERTIES R.

CLASS A FOAM CONCENTRATE. As a carbon-loving solution Class A foam soaks into solid combustible materials by breaking down the surface tension of the water. The fluorinated surfactants used in AFFF are produced by one of two synthetic processes 1.

The energy need to increase the surface area A is γδAδt so a low γ means more foam for less energy. Qualified to USDA Forest Service 5011-307a and UL approved for use as a wetting agent for Class AB applications. Costs for training Most departments did not quantify the cost of training their personnel to operate class A foam systems.

Difference was noted with nozzle-aspirated class A foam. PFOA and PFOS form a class of chemicals called perfluorinated compounds PFCs that act as surfactants to improve the effectiveness of Class B firefighting foams in fighting petroleum and other fires. Anionic surfactants create a lot of foam when mixed.

It reduces the surface tension of the water and. When mixed in correct proportions with water it can change two properties of the water.

A Taguchi Design Approach For The Enhancement Of A Detergent Biocompatible Alkaline Thermostable Protease Production By Streptomyces Mutabilis Strain Tn X30 Mechri Journal Of Surfactants And Detergents Wiley Online Library

Surface Active Agents Surfactants Types And Applications

Past And Present Of Functionally Graded Coatings Advancements And Future Challenges Sciencedirect

Nanomaterials A Review Of Synthesis Methods Properties Recent Progress And Challenges Materials Advances Rsc Publishing Doi 10 1039 D0ma00807a

Surface Dilatational Properties And Foam Performance Of Surfactant Nanoparticle Foaming System Under Ultra High Salinity

Surface Active Agents Surfactants Types And Applications

Use Of Low Medium High Expansion Foam In Firefighting Bioex

Surface Active Agents Surfactants Types And Applications

A Comprehensive Review Of The Chemical Based Conformance Control Methods In Oil Reservoirs Springerlink

Surface Active Agents Surfactants Types And Applications

Surfactant Sodium Lauryl Sulfate Enhances Skin Vaccination Molecular Cellular Proteomics

Anionic Surfactant Induced Changes In Skin Permeability Journal Of Pharmaceutical Sciences

How To Make A Natural Shower Gel Using Surfactants Formula Botanica

Surface Active Agents Surfactants Types And Applications

Use Of Low Medium High Expansion Foam In Firefighting Bioex

Adding A Punch To Fire Attack Enhanced Water Streams Firehouse

Analysis Of Surfactants By Mass Spectrometry Coming To Grips With Their Diversity Pascale Mass Spectrometry Reviews Wiley Online Library